ATANE is providing Construction Engineering and Inspection (CE&I) services to the Connecticut Department of Transportation (CTDOT) for Route 17 On-Ramp to Route 9 Northbound (Project No. 0082-0316) in Middletown, CT. (Estimated Completion Date: 2026).

The purpose of the project is to enhance safety for vehicles at the on-ramp of Route 17 onto Route 9 Northbound, which has a high frequency of rear-end crashes. The existing ramp from Route 17 to Route 9 is a skewed stop-controlled on-ramp with a short acceleration lane. The lack of a standard acceleration lane is due to the limited roadway width of the bridge immediately north of the on-ramp which carries Route 9 over Union Street and an active Providence and Worcester rail line. The project will replace the existing bridge in a multiple stage process that will reuse portions of the existing structure while maintaining rail service to provide a full-length acceleration lane and remove the stop-controlled condition. The new bridge will be supported by hundreds of micropyles, and the steel girders will be metallized and painted.

The Harbor Drive on-ramp to Route 9 will be removed and Harbor Drive will be reconfigured as a low speed, pedestrian friendly, local access road serving the Connecticut River riverfront and adjacent properties. The Project will provide additional pedestrian access across Union Street on the south side. There will be extensive landscaping to beautify the area.

The Route 17 interchange at Main Street Extension will be re-aligned and signalized, and a new sidewalk will be added to the west side of Main Street Extension underneath Route 17. A noise wall will be installed on the Route 17 Northbound on-ramp. Route 17 Northbound will be reduced to 2 lanes from 3 lanes to simplify the traffic weave.

Retaining walls will be constructed on the west side of Route 9 with a simulated Brownstone facia.

There will be rehabilitation work on four other bridges within the project limits, including bridge deck wearing surface removal and resurfacing, concrete deck patching, membrane installation, parapet upgrades, and structural steel repair.

The whole Project will receive a final 2-inch overlay.

ATANE is providing Construction Engineering and Inspection (CE&I) services to the Connecticut Department of Transportation (CTDOT) for existing bridge coating removal and re-coating on 34 bridges in District 4, CT. (Estimated Completion Date: 2025)

CTDOT issued an Emergency Declaration and ATANE was selected to provide the CE&I services under our Task-Based Agreement.

The purpose of this Emergency Declaration Construction project is to address a sudden loss of adhesion of the paint system to the base metal impacting bridges across the State. As a result of an unknown event, possibly a severe drop in temperature following a relatively warm period during the winter of 2023, dozens of older paint-coated structures exhibited this sudden loss of adhesion. This resulted in large quantities of paint chips, some potentially including lead-based paint, falling off the structures.

The remaining loose paint on thousands of square feet of steel beams will be removed as well as the reapplication of a protective coating.

The locations and geometry of the bridges vary significantly, from single span structures in rural areas to multi-span structures over I-84, and complex structures carrying I-84 over local roads and railroads.

ATANE was recently selected to provide Construction Engineering and Inspection (CE&I) services to the Connecticut Department of Transportation (CTDOT) for upgrading cameras (CCTV), traffic flow monitors, fiber optics and communications on portions of I-95 and installing the same type of equipment on Route 7 in Southwest Connecticut.

The purpose of this Project is to upgrade and expand CTDOT’s Intelligent Transportation System (ITS), which includes the Incident Management System (IMS) components installed on this Project. The CCTV camera system throughout Connecticut is a vital element in CTDOT’s overarching ITS program. The real-time traffic condition information provided by CCTV camera images, accessible on CTDOT’s website, serves as a valuable resource for CTDOT, the media, and the travelling public. CTDOT has strategically installed CCTV cameras and traffic flow monitors along all major limited access highways as part of its ever-growing ITS program. Leveraging technologies like CCTV cameras, traffic flow monitors, and electric message signs, CTDOT can effectively monitor and gather information on traffic conditions. This enables the effective management of traffic, swift incident detection, the dispatch of the appropriate response, and offers motorists advance notice of congestion. This proactive approach reduces the possibility of secondary accidents and allows the motorists to explore alternate routes, travel modes, or adjusted travel times.

The primary objective of this Project is to enhance safety, alleviate congestion, and improve traffic flow.

The system installations will include the following:

Traffic congestion, railroad inefficiencies, low bridge clearance, roadway flooding, and an aging bridge structure resulted in a “perfect storm” of transportation infrastructure problems that led to the replacement of the Atlantic Street Bridge on the Metro-North Railroad (MNR) New Haven Line. Maintaining uninterrupted train service along this primary commuter route while replacing the five-track structure made Atlantic Street a perfect candidate for accelerated bridge construction.

The project made use of several ABC techniques in addition to the self-propelled modular transporters placement method for the structure. Construction activity was coordinated with available track outage schedules. Prefabricated components were transported to the site and rapidly installed, including ten temporary railroad jump spans, six permanent bridge decks, and 18 plate girder pier columns. The project team completed multiple concurrent operations to prepare the site while the superstructure was built remotely.

The use of jump spans allowed construction to continue beneath active train traffic. Founded on a soldier pile and lagging system using micropiles, they supported live train loads and retained the existing rail bed embankment. Each jump span carried one track while allowing for abutment work and excavation to take place beneath the railroad and normal train operations to continue above. Vehicular traffic and pedestrian access under the bridge were maintained until late in the schedule.

The $78.5 million project improved accessibility to the South End of Stamford and improved operational efficiencies along Atlantic Street while simultaneously replacing the outdated railroad bridge. These improvements will facilitate future development in the South End and increase connectivity between the South End and Stamford’s downtown. Atlantic Street, under the new bridge, was widened to accommodate three SB and three NB lanes and lowered to provide a minimum clearance of 14’6” to allow for emergency and commercial vehicles. The project also added a new dedicated Track #7 for local train service along with catenary and platform improvements to the train station.

The bridge was rolled into place from June 28 to July 7, 2019 without any delays or service disruptions to MNR customers. The roadway underpass was reopened within months, whereas traditional construction would have taken years and entailed extensive roadway detours and train service disruptions.

This project received an ACEC NY 2020 Gold Award for Engineering Excellence, an ACEC CT 2020 Engineering Excellence Award and the Accelerated Bridge Construction Conference 2019 Best ABC Project in the Self-Propelled Modular Transporter/Railroad Bridge category.

The Town of East Hartford is reconstructing 3,200 feet of Brewer Street. The work will begin at Main Street (S.R. 517) and extends east of Glenn Road and includes the replacement of Bridge No. 042012 over Pewterpot Brook.

ATANE provides construction and engineering inspection and material testing services for the project throughout its construction. The project will include full-depth roadway reconstruction and granite curbing on both sides of the road. A five-foot sidewalk and grass strip will be reconstructed. Improvements also include new ADA ramps, signing and pavement markings, and midblock crosswalks with concrete pads at the bus stop locations. The existing drainage system along the limits of the project will be replaced with added hydrodynamic separators for water quality. The radius at the southeast corner of the intersection with Main Street will be modified to accommodate large vehicle traffic. The signals at the intersection with Contractors Road and Glenn Road will be replaced with new equipment and the intersection will be realigned for efficiency. The Intersection realignment will include modifications to install a right turn slip ramp onto Brewer Street and accommodate turning movements for large vehicle traffic onto Contractor’s Road.

As part of the project, Bridge No. 042012 will be reconstructed. New abutments will be constructed inside cofferdams, new girders installed, and a new deck will be poured. The project is in a densely populated area and will require the shutdown of Brewer Street for the bridge installation. Extensive coordination with stakeholders and the public will be required to ensure the change to the traffic pattern is performed with as little disturbance to the traveling public as possible. Our inspectors will be responsible for ensuring that the reconstruction is performed in strict accordance with all applicable contract documents, Including Form 818, CTDOT Construction Manual, and the MSAT Project Manual. This work is slated to take 2 years and will be performed at a cost of $7.8 Million.

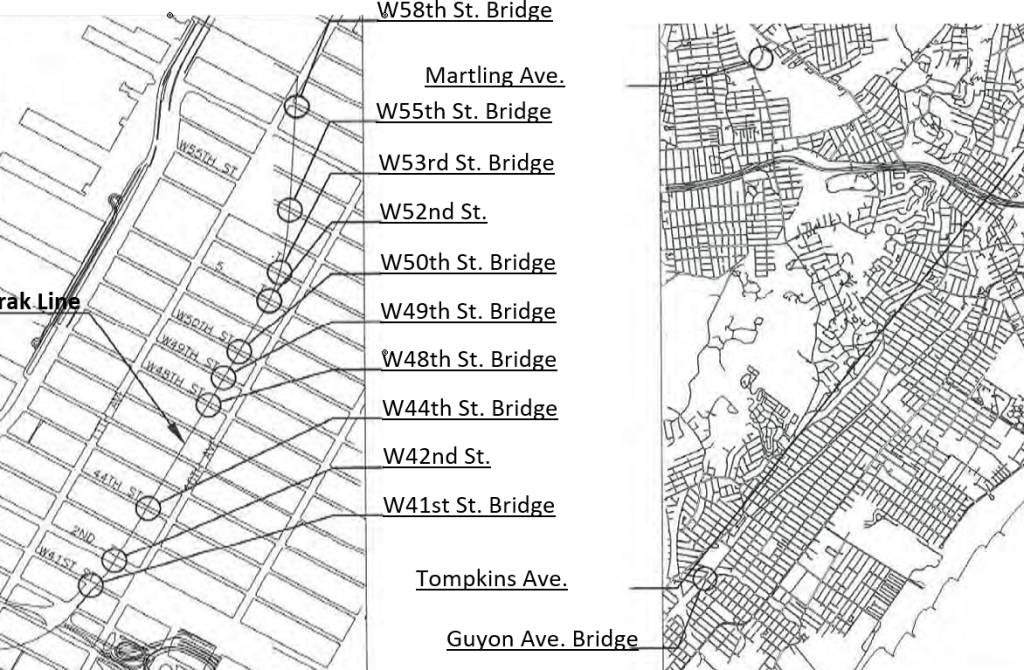

ATANE is providing Resident Engineering Inspection (REI) services to the New York City Department of Transportation (NYCDOT) for component rehabilitation of 13 bridges in the boroughs of Manhattan and Staten Island (10 in Manhattan, 3 in Staten Island)

The $26 million project includes deck and underdeck repairs, partial painting, roadway resurfacing work, curb and sidewalk work, abutment repairs, pier repairs, cleaning and recoating reinforcing steel, underdeck lighting replacement and installing new pedestrian chain linked fence in some of the bridges.

The ten bridges in Manhattan are located over the Amtrak railroad line, and one bridge in Staten Island is over the Staten Island Rail Transit (SIRT) ATANE is coordinating all aspects of the rehabilitation progress with the local communities, DOT, Amtrak and SIRT.

This rehabilitation project is scheduled for a three year period.

ATANE provided construction inspection services in Putnam County, to the New York State Department of Transportation in Region 8. The project scope included the reconstruction of the Taconic State Parkway between Pudding Street and Hortontown Hill Raod.

The work mainly comprised of mill and fill operations along the 4.7 mile stretch of roadway where the travel lanes were returned to a safe and drivable condition and reopened after each day/night shift. This project also included the improvement/replacement of drainage structurers, along the entire stretch of the Taconic State Parkway.

A critical achievement of the project was adjusting the cross-slope of the roadway and improving superelevation to provide a smoother, and more well-drained roadway profile. The scope also included the construction of 7,425 feet of concrete curbing, replacement/installation of all pavement markings, and the installation of new shoulder backup. This section of the Taconic State Parkway was brought into a safer configuration that is compliant with all state and federal guidelines.

ATANE provided Construction Inspection services for all work on this agreement including oversight of both the field and office operations. The duties included timely project closeout, accurate estimates, change order negotiations, and force account work. In addition, all other aspects of the project were managed by ATANE in accordance with MURK and to the satisfaction of the Department.